WOOD STABILIZING RESINS

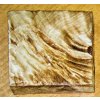

Wood stabilization is the process of vacuuming all the air from the wood and replacing the wood with resin. Regardless of the condition of the wood before the process (dry, withered or infested),very high pressure and vacuum are switched and a special resin penetrates the entire volume of the block, then the resin in the wood is allowed to harden (polymerize) and thus the wood is stabilized. The stabilized wood is used mainly by manufacturers of knives, weapons stocks, billiard cues, jewelry, non-traditional and luxury pens, exclusive bows, etc.

After stabilization, wood will increase its weight by 25-200 % depending on the type and condition of the wood (hard oak or ebony vs. spalled chestnut), the wood will strengthen, harden and significantly reduce its ability to continue "working". The stabilization releases the tension in the wood and thus eliminates its possible deformations. In addition, it becomes moisture-resistant, and its absorbency is approaching zero.

Wood stabilizing resins are most often used on the basis of acrylates and epoxies.

Acrylic stabilizing resin - Veropal WSB A (WSB = wood stabilization; A = acrylate) are used on wood more compact and harder, only with microcracks. Its advantage is that it is one-component and that it can be used repeatedly after activation with proper storage in the cold (preferably in the refrigerator). That is, pour the rest back into some container after stabilization, close and store in the refrigerator. After a time of, for example, 2 months, this resin can stabilize some other wood. The disadvantage is that the acrylates need a higher temperature (85-95 ° C) for polymerization, so the stabilized wood is wrapped in foil and placed in an oven or oven at the desired temperature for 2 hours.

Epoxy stabilizing resin Veropal WSB E-LV (WSB = wood stabilization; E = epoxy; LV = low viscosity) is used for softer woods, with larger cracks, knots and holes or for large pieces (planks or their parts). It is a two-component resin with a long workability time (up to 5 hours), very thin, run-in and well-absorbed into wood. After mixing components A and B, slow polymerization begins, so it cannot be used repeatedly. Cures at normal temperature (approx. 1.5-2 days). The process can be accelerated in the same way as for the curing of Veropal WSB A acrylic resin.

Bestsellers

Brands

Certifikace styku s potravinami

DLE TYPU PRYSKYŘICE

MAX. VRSTVA LITÍ

TYP VÝROBKU

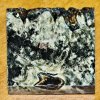

VEROPAL WSB PR BLACK is a highly concentrated black dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

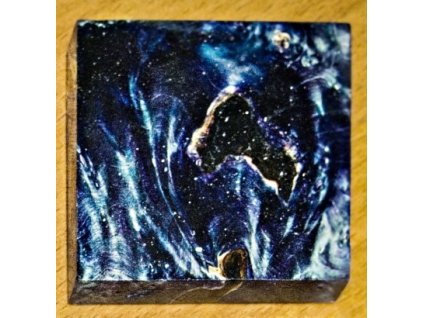

VEROPAL WSB PR BLUE is a highly concentrated blue dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

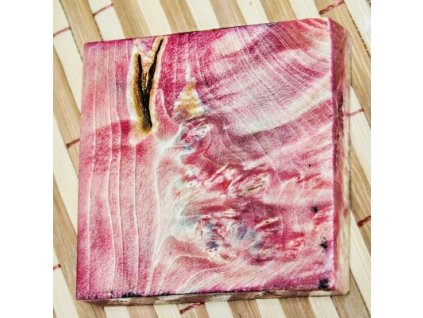

VEROPAL WSB PR BORDO is a highly concentrated bordo dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

VEROPAL WSB PR BROWN is a highly concentrated brown dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

VEROPAL WSB PR GREEN is a highly concentrated green dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

VEROPAL WSB PR ORANGE is a highly concentrated orange dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

VEROPAL WSB PR RED is a highly concentrated red dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.

VEROPAL WSB PR YELLOW is a highly concentrated yellow dye for coloring epoxy and acrylic stabilizing resin when stabilizing wood or other porous materials.