CHS EPOSTYL 521-01 – Cast Epoxy Seamless Flooring

Code: 8026/RAL 8026/26K 8026/26K2 Choose variantProduct detailed description

DESCRIPTION

EPOSTYL 521-01 is a cast pigmented binary flooring. Part A is made predominantly of a modified low –molecular epoxy resin, refined by suitable fillers and colored by a pigment at the option of a customer. Part B is a curing agent.

USES

EPOSTYL 521-01 is commonly used to create seamless floor of buildings intended primarily for civil or industrial occupancy. EPOSTYL 521-01 in thickness of 2-3 mm is fitted for floor of

- Warehouses, storehouses, parking garages,

- Showrooms, exhibition space, Shopping centers,

- Production and storage halls,

- School facilities.

PROPERTIES

- Higher UV resistance,

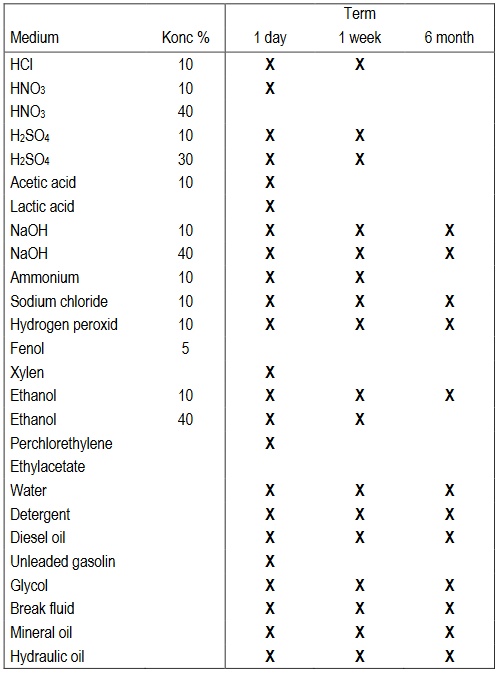

- Chemical resistance (see resistance table),

- Easy applicable & uncomplicated cleaning,

- Available in a wide variety of the RAL colors and shades,

- Excellent adhesiveness to the concrete foundation.

STORAGE AND TRANSPORT

Product must be stored and transported in original closed packaging at temperature 5-25 °C, always separately from hardeners and sources of ignition. Warranty period for the product is 12 months after the date of production provided that proper storage and transport conditions are kept.

INSTRUCTION FOR USE

IMPORTANT NOTES BEFORE USE

Respect recommended storage conditions. Store in temperature between 5 °C and 25 °C in a dry area separately resin and curing agent.

Before start working, make sure you understand the application guidelines and principles of the safe working method.

1. PENETRATION

1.1. Surface Preparation

- Concrete substrate should be dry, flat, without any crack, seasoned at least 28 days. It should be insulated against bottom moisture or provided with cellars.

- The surface should be smoothed with wooden or a felt smoother, and should not be sprinkled with cement.

- The surface should be clean. When damaged or contaminated with dust, fat or oil stains, asphalt, wax, old paint or other impurities sweep, blast or abrade it well.

- In case the surface is prepared, and concrete substrate meets all requirement (see next table), penetration can be carried out. The goal is to toughen the surface and to displace water from the substrate.

Basic parameters which concrete substrate should show

- Compression strength for driving (class III) min. 21.5 MPa,

- Compression strength for walking (class II) min. 14.7 MPa,

- Humidity max. 4 wt. %,

- Adhesion min. 1,5 MPa.

1.2 Suitable systems for Penetration:

- Water-borne EPOSTYL 200 V (see Application sheet EPOSTYL 200 V),

- Solvent-free CHS-EPOXY 474 / TELALIT 0492.

2. FLOORING APPLICATION

- The flooring can be applied only when the temperature is suitable (see TECHNICAL DATA).

- The flooring can be spread first 24 hours after the penetration.

- Flooring is usually applied in a thickness of 2-3 mm. Roll immediately with a spiked roller to ensure uniform thickness and remove entrapped air.

2.1. Preparation of the flooring

- Stir EPOSTYL 521-01 part A first to uplift all the pigments particles and to homogenize fillers.

- Blend in a correct quantity of Part B (curing agent) while stirring to the Part A.

- Mixture should be poured into another vessel and stirred shortly again.

- Do not prepare more material than can be comfortably applied within the pot life.

- The pot life is roughly 30 minutes at room temperature. It becomes significantly shorter by higher temperature.

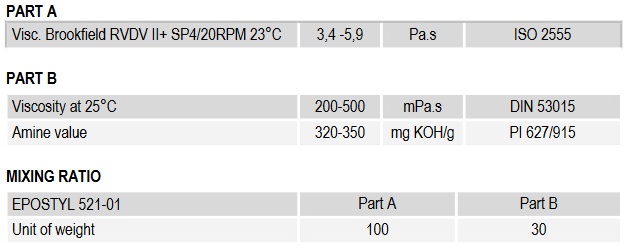

2.2. Mixing ratio

EPOSTYL 521-01 part A 100 by weight + EPOSTYL 521-01 part B 30 by weight

2.3. Mixing time

Stir the mixture 2-3 minutes after the relevant quantity of part B has been added to part A, then pour the mixture into another vessel and stir for the next 1-2 minutes before application.

CLEANING

Clean all tools and equipment immediately after use. Clean them with organic solvent based on acetone. Once hardened, the tool can be cleaned mechanically. If skin becomes soiled, wash off immediately in hot soapy water.

MAINTENANCE OF FLOORING

- 1-3% detergent solution in warm water is an optimal washing-up liquid for cleaning both public and industrial floors.

- If hot water is required for cleaning, be sure that the flooring system has been properly cured.

- Pretty greasy floors can be cleaned with solutions containing a detergent with a maximum 2% sodium hypochlorite, soda or caustic alkali.

- Use white spirit or denatured alcohol if necessary to use any solvent. The use of aromatic and oxygen-containing solvents incl. acetone, butyl and ethyl acetate is not recommended.

- Avoid the use of cleaning agents meant for cleaning stoneware. These agents contain organic acids such as formic acid, acetic acid, etc. in concentrations exceeding 5 %.

- Dry cleaning should be avoided within the first three days of the installation and could be used after the coating has cured perfectly.

- Machine cleaning should be applied minimum 10 days after the installation.

HANDLING PRECAUTIONS

- Protective equipment during handling should include face shield or goggles and gloves. Avoid contact with the eyes or skin.

- Exhaust working space thoroughly to avoid breathing vapor.

- Wear protective gloves when mixing or applying coating.

- If eye contact occurs, hold eyes open, flood with water for at least 15 minutes and seek first aid. If skin contact occurs, remove contaminated clothing and wash skin thoroughly.

TECHNICAL DATA

Form Part A is a modified low –molecular epoxy resin, refined by suitable fillers and colored by a pigment at the option of a customer. Part B is curing agent.

Color

The product is available in following RAL colors and shades:

- Grey RAL 7001, 7012, 7032, 7035, 7044, 7046

- Pale ocher RAL 1014, 1017

- Green RAL 6002, 6019, 6021

- Grey white RAL 9001, 9010

- Others shades by prior arrangement

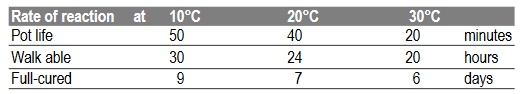

Pot life & curing times

Properties of system

- Gelatinization at 23 °C: max. 4 hrs.,

- Total color difference DE: max. 1.

Limit air and substrate temperature for application

- Minimum +15/+10 °C,

- Maximum +30/+30 °C.

Mechanical properties of cured flooring

- Flooring hardness after 24 hrs/23 °C: min. 65 MPa,

- Linear shrinkage after curing: max. 0.20 %,

- Linear shrinkage after post-curing 3 days/80 °C: max. 0.35 %,

- Water absorption after 7 days/23 °C: max. 1.20 %,

- Compression strength: min. 150 MPa,

- Bending strength: min. 50 MPa,

- Impact resistance: min. 8 KJ/m2,

- Tensile strength: min. 40 MPa,

- Tensibility: min. 3 %,

- Gripping: min. 5 MPa,

- Abrasion resistance: max. 50 mg.

CONSUMPTION

- Primer: EPOSTYL 200 V or CHS-EPOXY 474/ TELALIT 0492: min. 0.7 kg/m2 per one coat (depends on porosity and surface texture of the substrate),

- EPOSTYL 521-01: 2,3-3,5 kg/m2.

CHEMICAL RESISTANCE TO THE DIFFERENT MEDIA

Additional parameters

| Category: | EPOXY RESINS |

|---|---|

| Warranty: | 1 year |

| Certifikace styku s potravinami: | Ne |

| UV stabilita: | Vysoká |

| DLE TYPU PRYSKYŘICE: | PODLAHY |

| TYP VÝROBKU: | LITÁ PODLAHA |

| Míchací poměr: | 100:30hm% |

| Doba zpracovatelnosti: | 50min (10°C), 40min (20°C), 20min (30°C) |

| Doba vytvrzení (pochozí): | 30 h (10°C), 24 h(20°C), 20 h(30°C). |

| Doba vytvrzení (úplná): | 9 dní (10°C), 7 dní(20°C), 6 dní(30°C) |

| Spotřeba při aplikaci penetrace: | 1,4kg/m2/1mm; 4,2kg/m2/3mm |

| Balení: | 26kg |