Veropal UV plus (Our best)

Veropal UV Plus are transparent, optically clear glass, UV stable (non-yellowing), epoxy casting resins with extended processing time. This resin has food contact certification and health certificate.

3 versions

Veropal UV Plus 100 – Slow version (cures up to 96 hours). This clear resin is intended for the application of a very large amount of material at once – this system allows processing and casting at once a volume of up to 50 l and a thickness of up to 10 cm. It has an extremely low exotherm and shrinkage, which is compensated by a very long curing time (up to 96 hours) depending on the amount cast and the thickness of the layer during application. The casting is hard and tough.

Veropal UV Plus 121 – Fast version of the resin (hardens in 24 hours to 1.5 cm). The cast is very hard but more brittle. This version of the resin replaces the original Veropal UV PLUS 120. More sensitive to air humidity.

Veropal UV Plus 130 – Medium speed version of the resin created for medium volume applications (up to 10 l). Hardens within 48 hours at 5 cm.

All types of these casting resins are low-viscosity, very fluid, penetrate well, and after curing, the castings have the same refractive index as glass.

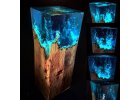

Veropal UV Plus casting resins are mainly used for casting of tables, casting of wood in the production of luxury furniture or doors and for the production of water-clear and transparent castings, jewelry, advertising and decorative items, etc.

As the main application of Veropal UV Plus resin is in the coating of tables and in the production of interior design furniture, we had tested this system for health safety in accordance with the requirements of Decree of the Ministry of Health No. 6/2003 Coll. Emission of volatile organic substances will not exceed the hygiene limits specified in the Decree of the Ministry of Health to be exceeded. No. 6/2003 Coll.

Veropal Transparent (Middle ground)

Clear casting resin Veropal Transparent is a two-component transparent epoxy system characterized by low viscosity and slower curing at normal temperatures. Due to the effect of UV radiation, this resin turns slightly yellow over the years and acquires a natural slightly yellowish resin shade. It shrinks only minimally during curing. The hardness of the casting is regulated by the mixing ratio from a hard 75 Shore D at a ratio of 100 : 50 to a flexible 60 Shore A at a mixing ratio of 100 : 100. The material is practically odorless, it can be easily colored and pigmented. To achieve faster hardening, the material can be tempered to a temperature of 40-60 °C for several hours (after the transition to the gel phase). This will speed up the curing. It is used in almost all types of castings, from tables, clocks, cutting boards to jewelry.

3 versions

Veropal Transparent 200 – Slow version (cures up to 48-72 hours at normal temperature) this system allows processing and casting a volume of 20 l at the same time. Processing time approx. 6 hours.

Veropal Transparent 230 – Medium fast version (cures approx. 36-48 hours at normal temperature).

Veropal Transparent 250 – The fast version is intended for smaller castings up to a volume of approx. 500 ml. The system has a shortened curing time (approx. 24-36 hours at normal temperature) with minimal shrinkage and a processing time of 60 min.

Veropal Clearcast (Excellent price/properties ratio)

1 version

Veropal Clearcast 300 is a clear casting epoxy resin characterized by very low viscosity, minimal shrinkage and curing at normal temperatures. It is an economical variant of the casting resin, which has a lower UV protection compared to Veropal UV PLUS and Veropal Transparent. It achieves a slight yellowish transparent shadow over time. However, compared to resins on the market in this price range, it is one of the more UV resistant. The mixing ratio of component A and component B is 100 : 40, resulting in a thin, clear liquid with a sufficiently long shelf life. The cured system has a clear glassy appearance with a hardness of 75 Shore D. The curing time is 2-3 days; the maximum recommended volume of casting at one time is 20 l at a maximum thickness of 5 cm. It is used wherever there is no need for high UV protection – e.g. for the production of some heavily pigmented epoxy tables and furniture, the production of transparent castings, advertising and decorative objects, as well as for various testing or the first introduction to the resin.